Radiation Hazards and Control

Radiation hazards, routes of intake of radioactivity, radiation hazards control measures, defense-in-depth/zoning approach, handling facilities, time, distance, shielding approaches, measurements of the exposures.

Like electricity, working with radiation can also be made safe to maximize the societal benefits. Though it is potentially hazardous, usage of electricity is made safe by design and strict follow-up of the operating procedures. Similarly, radiation can be safely employed to derive maximum benefits in its applications in medicine, industry, and agriculture.

Radiation hazards

External exposure

In work places, workers may be exposed to external exposure from radiation sources that are external to the body. Exposure from an industrial radiography source, exposure from a Co-60 or Cs-137 source used in medical or research applications, and exposure of humans to natural radiation source like cosmic radiation from space are the examples of external exposure.

Internal exposure

Internal exposures result from sources which are inside our body. Radiation sources get incorporated in the body due to inhalation of contaminated air or ingestion of contaminated food and water. Examples are K-40 and uranium/thorium/radium isotopes. Radon and Thoron are gaseous radionuclides generated in the decay chain of U-235 and Th-232. These radionuclides with short half-lives get mixed up in the air we breathe, and give significant amount of radiation dose to the lungs.

Personnel working in mines and monazite mineral handling facilities get inhalation of radon present in environment and exposure from the occupational intakes through inhalation or ingestion. Intakes may also result from a contaminated wound (injection), and absorption of radioactive materials by the skin. Tritiated water (water contaminated with tritium) is absorbed easily by the skin. Inhalation is the major route of intake of radionuclides in operational settings.

The inhalation hazard increases with the decrease in aerodynamic particle size of the radioactive aerosols present in the work environment. ICRP Reference values for regional deposition in the respiratory tract (R.T.) of inhaled 5µm particulates in workers engaged in light activity, breathing through nose, is given below:

Pattern of percentage deposition of inhaled 5µm diameter aerosols in the respiratory tract (R.T.)

| Region of the R.T. | Description of the region | Percent deposition of the inhaled activity |

| ET1 | Extra-thoracic region including anterior nasal passage | 47.94 |

| ET2 | Extra-thoracic region including posterior nasal passage, pharynx and larynx | 25.82 |

| BB | Bronchial region | 1.78 |

| bb | Bronchiolar region | 1.10 |

| AI | Alveolar Interstitial region | 5.32 |

| Total | 81.96 |

Note: Particles are assumed to have a density of 3 gm /cm3; Shape factor – 1.5

As could be seen, smaller particles penetrate deeper in the lung and hence are more hazardous. Depending on the absorption type of the inhaled particles (Fast, Medium and Slow-type), the deposited radioactive materials are transferred from the lung to blood and get cleared from the body through excretion.

Radiation hazards control measures

Radioactive materials are handled in suitably designed facility which is well-identifiable, and its access is controlled. Inside the facility, the work areas are classified into different zones. The zoning of the areas is carried out to prevent spread of contamination in the areas (Table 3). The areas are classified as White, Green, Amber, and Red zones. Expected radiological status - such as radiation levels, air activity and radioactive contamination levels; personnel clothing, access controls and ventilation requirements in these areas are given in the table. Suitable barriers are erected to separate the different areas, with additional shoe covers at the barriers. This is normally followed in the design of radioactive laboratories.

Zoning criteria may be different depending on the type of radionuclide and the nature of operations. The number of air changes in different zones vary depending on containment requirement and the potential for spread of contamination. Comfort of the radiation workers in the areas is also a consideration. Directed air flow patters ideally should be from green to amber and to red. From red areas, the contaminated air is exhausted from the top of the building, after HEPA filtration.

Classification of areas

Typical classification of areas in radioactive laboratories

| White zone (Clean zone) | Green zone (Buffer zone) | Amber zone (Restricted entry zone) | Red zone (No entry) | |

| Entry | Unrestricted | Entry with plant issued footwear and lab coat | Entry with full plant clothing, gloves and over-shoes | Entry only with protective clothing and respiratory protection |

| Personal monitoring requirements | No individual monitoring | Individual monitoring, TLD/Film badge | Individual monitoring, both internal and external, TLD/Film badge | Individual monitoring, both internal and external, TLD, / Film badge, Pocket dosimeter with alarm |

| Area monitoring | Occasional to confirm status | Regular to confirm status | Continuous/routine area/air monitoring with alarm | Monitoring whenever required |

| Air activity levels | Background | < 0.1 DAC | < 1 DAC | Expected to be high |

| No. of air changes/h | 3-4 | 6-8 | 8-15 | Can be as high as 25-40 |

| Inter-zone pressure gradient (in WG) | 2 mm between white and green 5-10 mm between green and amber 15-45 mm between amber and red | |||

| Area contamination | Not in normal courses | < 0.1 DWL | < 1 DWL | Expected to be high |

| External radiation dose | Ambient levels, generally, Less than 1 micro Sv/h | < 3 microSv/h, Full occupancy | ≤ 10 microSv/h | Expected to be high |

Notes:

- The numbers may vary as per prevailing national regulations

- All personnel exits from different zones should be monitored.

- Access to various zones should be from white to green to amber

- Hand and foot monitor should be provided at cross-over barriers between zones

- Materials exiting from amber to green to white should be monitored.

- Vehicle/material exit points should not be used for personnel traffic

- Full occupancy is 8-hour presence in the area

Handling facilities

Containment is an important aspect in ensuring safety while handling radioactive substances. For the purpose, facilities such as fume hoods, glove boxes, shielded boxes and hot cells are provided in amber areas. A considerable degree of built-in safety is provided in these containment facilities. Amount of radioactive substance that can be handled in the facilities vary depending on the radio-toxicity and the nature of operation to be carried out. These numbers are specified by regulators.

Fume hood

A fume hood is an enclosure in which the radioactive material is handled. Fume hoods are used when the contamination, and external exposure hazard is low. Simple chemical operations may be carried out in fume hoods. Front opening in the fume hood provides work space and passage for the amber area ventilation air to provide the number of specified air changes. Normally, micro to milli Curie levels of beta activity are handled in fume hood. Services provided in fume hood are usually water, gas, compressed air, vacuum and electricity.

Glove box

A glove box is a leak-tight enclosure in which open radioactive sources can be handled in isolation from the user’s environment (lab within a lab). The glove boxes are used for handling of certain alpha emitters (e.g., plutonium). Heavy duty gloves (gauntlet) fixed to open ports in the generally transparent walls of the box. The exhaust from the box is adjusted to provide about 1” W.G. negative pressure inside the glove box.

In an enclosure, at the inside top of the box, absolute filter is provided for the exhaust air to pass through. Portholes with air-lock are provided for material transfer. The normal leakage rate of 0.5% of the box volume per hour provides about 4-5 air changes per hour in the glove box. Services such as electricity, vacuum, compressed air, effluent drainage, etc. are provided inside the box.

Maintenance of adequate negative pressure, and periodic checking of the gloves for pin-hole leaks, are important safety considerations in glove box operations.

Shielded box

A shielded box cell is a shielded air-tight enclosure fitted with provisions for remote handling, which allows the performance of operations without subjecting the operators to radiation exposure beyond the acceptable dose rates.

Depending upon the energy of the gammas, shielded boxes are used to handle beta gamma emitters of millicurie to a few curie levels. Remote handling tongs are used in these boxes. The walls are constructed with lead bricks for shielding radiation. Ventilation in shielded boxes is similar to that of glove boxes. Sufficient numbers of air changes are provided for promoting good visibility and to dilute sufficiently the airborne activity levels inside the box. The exhaust from the shielded box passes through double HEPA filtration to remove all the particulate and gaseous radioactive materials before it is discharged into the environment. Various services are provided inside the box. Sufficient negative pressure is maintained all the time.

Hot cell

A hot cell is also a shielded enclosure with systems of manipulation to allow the performance of almost all operations inside the cell. The main construction material for hot cells is concrete (density ~2.4 g/cm3) which is relatively cheap and density can be varied to suit requirements. Generally, the walls of the hot cell have shielding of 1 to 1.5 m of concrete.

Hot cells are used for handling high intensity sealed sources of kilo curie levels. The working surface inside the cells is usually stainless steel. Various services such as water, steam, chemicals, viewing window and even welding unit are provided inside the hot cells. Master slave manipulators are used for the remote operations. Well-trained personnel are required for such operations. Doors made of steel are provided for access to the cells for decontamination and maintenance. Special materials such as transparent lead glass windows provide unrestricted view to the operators.

Sufficient ventilation (~25 - 40 air changes per hour), with absolute filters (for double filtration) at the exhaust end is provided before the exhaust air is released into the environment. Penetrations of the service lines on the walls are so designed as to prevent any streaming or leakage of radiation to the work areas outside the cell. The cells are kept normally under negative pressure to prevent league of contaminated air into the operating area.

Controlling external exposures

In case of beta rays, the skin is the target organ, the rays can not penetrate beyond skin. The alpha particle can not penetrate insensitive layer of the skin, and hence not considered for the external exposure.

Source

It is important that the involved source details, such as type of radionuclide, the radiations, and the optimum source strength, are used for the purpose of assessing personnel exposures and the control measures.

Time

The less the time spent in a radiation field, the less the exposure. Hence, it is advised to plan any job in the radioactive area in advance, do mock operations if possible, and complete the job in minimum time.

Distance

Radiation intensity reduces when one moves away from the source. The intensity of radiation from a point source at a given point is inversely proportional to the square of the distance. The relation followed for such calculation is:

The exposure rate (in the classical units of Roentgen / h) = 0.53 n C E/ R2

Where C is the source strength in Curie, E is the energy of the gamma photon in MeV, n is the yield of the photon, and R is the distance from the source in meters.

Shielding

Interposing or erecting a shield between the personnel and the source can reduce radiation exposure. Commonly used shield materials are soil/sand, water, concrete, steel and lead. In some situations, depleted uranium is also used. Denser material acts as better shield for X-rays and gamma rays. Perspex is a good shield for beta particles. Hydrogenous materials such as paraffin, plastic and water serve as good neutron shields. Cadmium, cobalt and gadolinium serve as good neutron absorbers. A thin sheet of paper can cut off alpha radiation.

The shield thickness to reduce the radiation intensity or radiation dose from a given source to one half of the initial value is called Half Value Layer (HVL), and the thickness required to reduce the intensity by one tenth of the initial value is called as Tenth Value Layer (TVL). One TVL is equal to 3.3 times the HVL. Typical half value layers for some radio-nuclides are given in the table below.

Half-Value Layer (HVL)

Radionuclide |

Major X-ray/ gamma-ray photon (MeV) | Half Value Layer in lead (mm) |

|---|---|---|

| Ra-226 | 0.2 – 2.4 | 11 |

| Cs-137 | 0.662 | 6 |

| Co-60 | 1.17; 1.33 | 11 |

| Ir-192 | 0.136 – 1.062 | 3 |

| I-131 | 0.365; 0.640 | 3 |

| Na-24 | 1.37; 2.75 | 18 |

| Fe-59 | 1.10; 1.29 | 13 |

| Co-58 | 0.81; 0.51 | 8.5 |

| Zn-65 | 1.115 | 13 |

Radiation survey of areas is carried out regularly to identify areas where the radiation intensities are higher. Caution boards are displayed to inform the persons working in the areas about the radiation levels. This helps in controlling the external exposures to a great extent. Area gamma monitors are also strategically located to indicate the radiation field to alert the personnel.

Radiation Survey instruments

Human senses are unable to feel the presence of Ionizing radiations. One has to fully dependent on the availability of appropriate detection and measurement systems to detect and assess the amount of radiation dose at any point of interest. Various types of electronic instruments are available commercially to detect and measure different types of radiations.

There are Installed radiation monitors, Portable radiation monitors and Personal radiation monitors. Very sensitive monitoring systems are required to detect very low levels of radioactivity. There are incidents reported on the finding of radioactive material in scrap, which ultimately finds its way into the freshly cast iron/steel with potential to expose members of the public. Since the nuclear reactor incidents at Chernobyl, and Fukushima, there are requirements world-wide for the detection and measurement of traces of radioactivity in foodstuff and consumer products. Increased threat perception from the terrorists, calls for development of state-of-the-art systems to meet the requirements of radiation detection and measurements at the national boarders and at all the entry points.

Controlling internal exposures

Inhalation is the major route of intake of radioactive materials while working in contaminated areas and in the areas where airborne activity is present. The control is achieved through good containment for the source and adequate ventilation to dilute the airborne activity.

Respiratory protection is provided for the personnel working in such areas. Equipment such as `Comfo’ respirators, with filter cartridges are used for protection against radioactive dust particles. Similarly, fresh airline respirators or gas mask / Self Contained Breathing Apparatus (SCBA) are used in situations with potential for large release of airborne gaseous/particulate activity or during jobs involving hazardous materials. The respirators should be sanitized and checked for contamination after use. Care should be taken not to contaminate the respirators. The protection factors for different types of respirators are given in the table below:

Air sampling is continuously done to measure the airborne radioactivity levels in the affected areas. The air is continuously sucked through filer papers at a constant rate using a suction pump. After sampling for certain time period, the filter paper is counted to measure the radioactivity content. Knowing the suction rate of the pump, one can find out the radioactivity concentration in the air. Respiratory protection is recommended if the air activity levels exceed a certain radio-nuclide specific value of Derived Air Concentration (DAC). During normal working of a plant the air concentration values remains a small fraction of the DAC.

Reported Protection factors (RPF) for respirators (to be confirmed from the manufacturer)

| Sr. No. | Type of Respirator | RPF |

|---|---|---|

| 1 | Particulate removing half-face piece (Comfo) | 10 |

| 2 | Particulate removing full face-piece | 50 |

| 3 | Gas and Vapour removing half-face piece | 10 |

| 4 | Gas and Vapour removing full face-piece | 50 |

| 5 | Self-contained breathing apparatus (SCBA), full-face piece (Pressure inside mask: negative) | 50 |

| 6 | Self-contained breathing apparatus (SCBA), full face mask (pressure inside: Positive) | 10,000 |

| 7 | Supplied air, half-face piece | 1000 |

| 8 | Supplied air, full-face piece | 2000 |

DAC value, in general differs depending upon toxicity of the radioactive content. Lower the DAC, more radio-toxicity of the radionuclide.

Contamination survey

Contamination is the presence of radioactivity in places where it is not desired. The levels of contamination on surfaces of floor and equipment can be determined by:

- Collecting Smear / wipe samples followed by counting

- Using Contamination monitors

Any area where contamination level exceeds the set limit or stipulated limit is cordoned off and decontaminated so as to prevent spread of contamination to other uncontaminated or clean areas.

External exposure measurement

External exposures of the personnel are determined at a given periodicity to ensure that regulatory limits are not exceeded, and the exposures are maintained as low as reasonably achievable (ALARA).

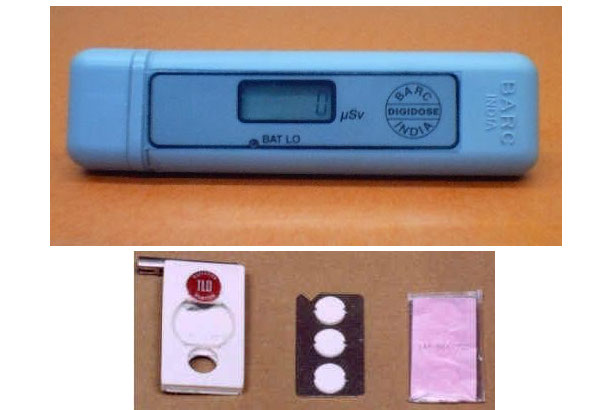

The radiation workers are provided with dosimeters, which are worn by the workers while entering the work areas. Generally thermo-luminescent dosimeters (TLDs) or Film badges are employed for the purpose. The badges are worn for certain number of days and processed to determine the exposures received by the workers. Often it becomes necessary to know the exposures immediately after certain work. Under such circumstances, readily readable pocket dosimeters or digital dosimeters, with alarm are used.

Thermoluminescent Dosimeters (TLDs) and Digital Pocket Radiation Dosimeter

Internal exposure measurement

In spite of well-designed containment provided for radioactive material while being handled, there is possibility that the radioactive material escapes the containment and contaminates the air outside the containment. The contaminated air is breathed by the workers, and they get exposed internally. The airborne contamination can also occur due to some incidents of spillages or leakages from the pipelines carrying radioactive materials.

The internally deposited activity migrates or translocate from the site of deposition and get metabolized in the body. Depending upon the physicochemical characteristics, the radio-nuclides get deposited in “preferred” or target organs. For example, iodine isotopes get deposited in thyroid, strontium in bone, Cs in muscles, uranium in bone and kidney and plutonium in bone and liver. Ultimately, depending upon the clearance half times (combined effect of biological half life of the material and physical half life of the radionuclide), the material gets excreted through urine and / or stool. The measurement of the amount of radioactive material present inside the body and the resulting internal dose estimates are done by the following methods.

- Whole body counting

- Thorax counting

- Bioassay

Whole body counting technique

In this method, the exposed person is directly counted for penetrating radiations emitted by the radioactive material, such as fission product activity such as Cs-137 present inside the body using a specially designed whole-body counting system.

Thorax counting technique

Internal contamination of insoluble alpha emitters such as uranium and plutonium are also assessed by lung (thorax) counting of the personnel in specially designed, low background whole body counting systems. Accidental intake of thoron and its progeny by occupational workers can also be estimated for the calculation of internal dose.

Bioassay

In this technique, excretion from the body urine, feces, etc. of the radiation workers are periodically analyzed for various radionuclides, which gives indication of the presence of radioactive material inside the body. The urine and/or feces samples are collected from the workers whenever exposure is suspected and as per the standard procedures, the samples are analyzed. The amount of activity, present in the samples can be used to determine the amount of the material present inside the body. The knowledge about the amount of activity inside the body is used to calculate the intake and the committed doses to various organs, as well as dose to the whole body taking into account the tissue weighting factors (For details: refer the book "Radiological Protection and Safety – A Practitioner’s Guide")